About the Author:

CEO at AlFiPa, responsible for operations as well as purchasing and sales. He is the primary contact for orders and deliveries within the company.

Aluminium foil laminated with paper

Aluminium foil can be used for multiple occasions or for different applications. Nevertheless, the outstanding characteristic remains certainly the ability to conduct energy.

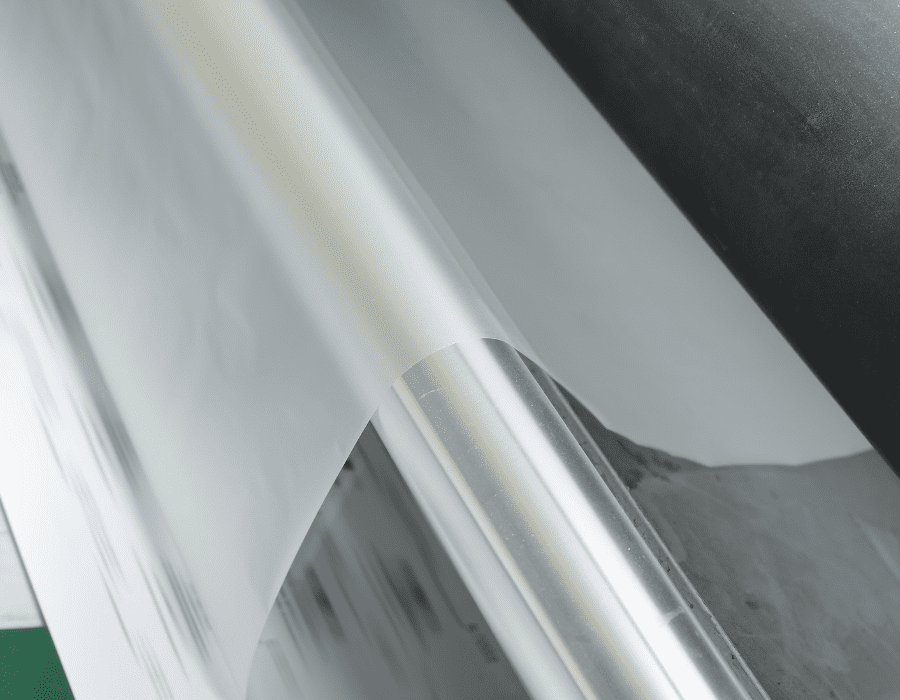

With composite films, i.e. films laminated with a different material, the advantages of the individual components are optimally exploited. Aluminium foil laminated with paper is also used for various areas and application examples.

Aluminium composite films are used, for example, to pack corrosion-sensitive products in water vapour- impermeable packaging.

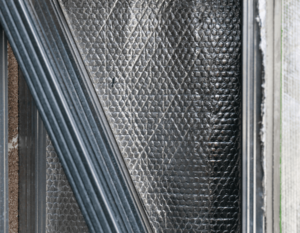

Aluminium foil laminated with paper is used as a so-called vapour barrier, for example in the construction industry.

In many respects, lamination with different materials makes sense because the advantages of two components can be used in this way. And because aluminium foil can be processed excellently, it is ideally suited as a carrier material.

Adhesive aluminium foil

Adhesive aluminium foil mostly used as aluminium-PP adhesive tape

Self-adhesive aluminium foil in the form of adhesive tape is used to insulate glass wool sheets or mats, for example. Adhesive aluminium foil can also be used to seal heating pipes.

Self-adhesive aluminium foils are ideally suited for sealing and insulation and also for bonding vapour barriers. Because whenever water vapour diffusion is hindered, an aluminium foil is required. This prevents an insulation layer from being soaked by diffusing water vapour. Vapour barriers must also be joined with adhesive aluminium foil in the sauna area. This means that insulation mats are joined together with aluminium foil and a layer, for example of glass wool or rock wool, by carefully joining them with adhesive strips of aluminium foil.

Adhesive aluminium foil

The advantages of aluminium foil are used sensibly in many areas of house construction and building services. Positive properties of individual components are also combined when aluminium foil is used. Adhesive components are coupled with aluminium foil. The result is adhesive aluminium foil, which is important, for example, for the processing of vapour barriers in house construction.

Adhesive aluminium foil can also be used for insulation in heating systems. In general, adhesive aluminium foils are also used as heat protection for components and surfaces against excessive temperatures.

Radiant heat makes sense. Here the use of adhesive aluminium foil at temperatures from -40 to approx. 250ºC is possible. Adhesive aluminium foil can also provide rapid help as a repair component. Due to their excellent heat and cold resistance, adhesive aluminium foil can also be used sensibly, for example, in building plumbing.

Aluminium foil coated

Coated aluminium foil

Coated aluminium foil is characterised by the fact that different components can be combined with a layer of aluminium foil, complement each other and all advantages can be used for the respective field of application.

There are many examples of this. For example, aluminium foil can be provided with an additional non- stick coating. This increases the tensile strength. The film remains dimensionally stable. In the food industry, coated aluminium foil is used for many types of packaging.

Tetrapacks are coated on the inside with aluminium foil and reinforced on the outside with paper. In building services, aluminium foil coated with adhesive can be used to insulate heating pipes. Coated aluminium foil can also be used in many ways for hobby purposes. The advantages of different components are also used there.

Printing on aluminium foil

Printing on aluminium foil is no problem with today’s printing methods. Printed aluminium foils, for example, are widely used in the food industry. Printed aluminium foil is also popular as gift wrapping paper. Aluminium foil can be printed using various printing techniques. There are hardly any limits to the imagination here. Whether coffee, butter, chips or also tablets. Without printed aluminium foil you can hardly imagine a supermarket or a pharmacy. Products can be kept fresh for many years without losing their aroma or emitting an odour. Printed aluminium foil does not lose its tear resistance and stability.

Aluminium foils are also printed on one or two sides in the construction industry so that the correct side can be used properly, for example, and processing errors cannot occur.

Aluminium foil gold

Aluminium foil gold

Golden Aluminium Foil – better known as First Aid Rescue Foil

Aluminium foils are available in various designs. The thickness or structure can also vary greatly depending on the intended use. The multiple application possibilities make aluminium foil a true all- rounder.

The golden aluminium foil is also an integral part of the first aid kit. It covers accident victims to protect them from hypothermia, moisture and other environmental influences. Also people with shock are covered or wrapped with golden aluminium foil to protect the injured person from a worsening of the symptoms.

The golden aluminium foil is a metallized plastic foil, which consists of a layer of thin, tear-resistant, transparent and waterproof polyester foil. An extremely thin, highly reflective aluminium layer is the second component. The result is a silver-coloured and an golden side, which is created by the aluminium foil shining through a yellowish polyester foil.

The golden aluminium foil can also protect against overheating, as it shields against solar radiation. The effect of golden aluminium foil is based on the reduction of heat transport by reflection.

Aluminium foil black

Black attracts warmth. Aluminium foil coated black on one side takes advantage of this simple physical law. And exactly this simple wisdom now appears as a new development in the modern kitchen. In comparison to conventional aluminium foil, the newly developed, black-coated aluminium foil transports the heat in the oven quickly and specifically around roasts and grills.

Compared to conventional aluminium foil, the grill or oven heat can thus be used much more efficiently. The grill food inside gets hot faster. It can also be observed that the grill food does not dry out.

The time saving is also significant, as the use of the black coated aluminium foil can lead to a saving of up to one hour. This also saves a lot of energy. Surface temperatures up to 100 degrees Celsius higher can be measured. So far there is only one well-known manufacturer of this new development. However, in the near future other manufacturers will certainly be launching similar products on the market. Up to now, the advantages have been conspicuous in comparison to conventional aluminium foils.

Aluminium foil strong

Aluminium foil is available in very different thicknesses and designs. The thickness or thickness can vary greatly depending on the application. Aluminium foils used in the food packaging industry have a significantly lower thickness than aluminium foils used in the construction industry. The strength of the aluminium foil naturally has a direct influence on the tensile strength and stability. Aluminium foil laminated with other components is often even stronger in the stress test. The thickness of the aluminium foils can vary enormously. Here the customer is offered many variants.

Risks of aluminium foils

Aluminium is a valuable raw material that is used in almost every aspect of everyday life. Whether in the construction industry, the automotive industry, the household or the cosmetics industry.

Everyday life in industrial countries is hardly imaginable without aluminium. But what about possible risks? It is clear that the production and processing of aluminium consumes large amounts of energy. But are there any additional health risks? Aluminium is suspected of being involved in the development of Alzheimer’s disease and breast cancer.

As aluminium is the most common element in the earth’s crust, it also appears in certain quantities in many foodstuffs. Especially in dried herbs but also in chocolate products.

However, only a small fraction of the aluminium in the food enters the body. Traces of aluminium can also be found in drinking water. In addition, most deodorants contain aluminium compounds, some of which can enter the body through the skin.

But where does the aluminium accumulate in the body? Traces of aluminium can be found in the bones and tissues of the brain or lungs. Alzheimer’s patients are thought to be associated with aluminium deposits and their disease. However, many studies are not convinced of this connection.

So far, the advantages of using aluminium have predominated. Nevertheless, one should pay attention to a moderate use of aluminium in daily life.

Aluminium foil causes Alzheimer’s?

Can the use of aluminium foil actually cause disease?

Doctors and scientists have come to the conclusion that this is probably possible. Apparently elevated concentrations of aluminium have been detected in the brains of Alzheimer patients. Current studies show that around 35 million people worldwide currently suffer from Alzheimer’s disease or other forms of dementia. Tendency rising. Several independent studies show that many Alzheimer’s patients have an increased concentration of aluminium in the brain.

According to a study, protein-containing deposits (so-called plaques) that can no longer be broken down in Alzheimer’s patients form around the foreign body aluminium. This is done to keep the harmful metal away from the tissue. But even if many scientists do not want to know anything about the connection between Alzheimer’s and aluminium, the use of aluminium foil in the household or in cosmetics should be restricted or at least questioned.

For example, unnecessary amounts of aluminium enter the body through the use of deodorants containing aluminium. Or by using aluminium trays in the kitchen, we also eat aluminium with every meal.

Aluminium foil for technical applications

Aluminium foil for technical applications

Aluminium foil has become indispensable in technical applications. Due to the multiple advantages, many technical applications became possible in the first place. The corrosion resistance, durability or electrical conductivity of aluminium foil can be decisive in technical applications. Even rolled to a thickness of 0.0007mm, aluminium foil remains completely impenetrable to light, aroma or flavourings. Technical applications requiring a high degree of corrosion resistance can be realised with aluminium foils. Many of these properties can be further improved by various surface treatments. Aluminium foil is also suitable for technical applications as an insulator against magnetic radiation or radio frequencies.

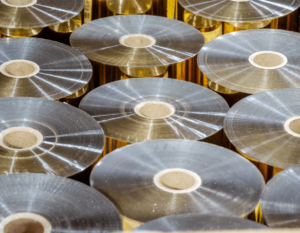

Technical aluminium foils

Technical aluminium foils are produced to exploit the barrier properties and reflectivity of aluminium for technical building systems.

Technical aluminium foils offer many advantages. For example, technical aluminium foils are not flammable. They are therefore elementary for fire protection. In addition, technical aluminium foils exhibit electrical conductivity. In addition, they can drastically increase the durability of many composites.

Glass fibre cables or electric cables can be shielded with technical aluminium foils. Fire protection regulations can be realised and implemented with technical aluminium foils.

Shielding with aluminium foil (e.g. wlan)

Shielding with aluminium foil from w-lan cables, for example, is often desired and necessary. As a sheathing, aluminium foil can also ensure a longer service life for cables. Aluminium foil can also protect against moisture similar to a vapour barrier or brake. Permanent insulation can be achieved by shielding with aluminium foil.

Corrosion-prone elements in electric cables can be protected in the long term.

Shielding with aluminium foil can always be useful if magnetic interference, even in highly sensitive areas, is to be dissipated. Shielding can also be useful against other cables or electronic circuits.

Aluminium foil for fire protection

Aluminium is a non-combustible material. Its melting temperature is over 600 degrees. This makes it highly relevant for fire protection. Aluminium foil is also especially preferred by fire brigades and fire protection. Fire protection also plays a very important role in building services.

Construction material must comply with German fire protection standards. Many insulation materials are therefore laminated with aluminium foil. Because both the thermal insulation is thus guaranteed, and the regulations for optimal fire protection can be provided. Significantly less weight is used with aluminium composites in fire protection. Which is useful for many types of lightweight construction. For example, weight plays a major role in the transport and automotive industries. But here, too, a great deal of attention should be paid to fire protection.

Aluminium foil and its refractoriness

Since aluminium has a very high fire resistance, this material is also very often used in fire protection. The melting temperature of aluminium is over 600 degrees Celsius. For this reason, aluminium can be excellently used in fire protection where fire resistance is required.

Fire resistance is now required in many areas. The material used in building services must also be fireproof. But also in traffic and fire brigades or in the automotive industry, for example. Refractory aluminium foils are used in combination with other composite materials to achieve the highest possible fire resistance. Because the melting point of aluminium is so high and the heat is so effectively reflected, aluminium can be used extensively.

Aluminium foil as reflector

Aluminium foil reflects heat

It is well known that aluminium can be used as a great conductor of energy. However, anodised aluminium (i.e. aluminium which has been protected against corrosion and abrasion by chemical treatment) can also be used as a reflector, for example, in a meaningful and almost replacement-free way.

In the lighting industry, for example, aluminium is used to reflect light rays like a mirror while still being heat-resistant.

The reflector material in lampshades is largely made of aluminium. The advantages of reflectors are complex. It is also good that one can change the increased luminance with different beam angles. For example, in luminaires and lamps it may be desirable to create different types of reflection.

Aluminium foil reflects heat

Aluminium, for example, reflects heat very effectively and without great scattering losses. Similar to a mirror, energy is dissipated in the form of heat or cold. That way, the heat can’t penetrate. This effect is often desired, for example, in building services. Heat, caused by solar radiation, is dissipated through aluminium foil, which is used in insulation, for example.

Aluminium foil is also used in roller blinds or windows to reflect the heat and ensure a pleasant living climate. Firefighters work with aluminium foil- reinforced suits that reflect heat and in some cases make their use possible in the first place.

Aircraft parts are coated with aluminium foil, which safely reflects the heat of the turbines as well as withstands the extreme minus temperatures at high altitudes.