About the Author:

CEO at AlFiPa, responsible for operations as well as purchasing and sales. He is the primary contact for orders and deliveries within the company.

Vapour barrier and vapor retarders

The question of whether a vapour retarders or a vapour barrier is better suited for renovation or new construction often arises. Both alternatives can be used to seal insulated building parts can be used.

- The advantage of a vapour barrier is that it does not let any moisture through as it’s steam-tight.

- With a vapour retarder, on the other hand, water vapour can escape in small quantities.

Sd-value

In this context there is often talk of Sd-values. The Sd value is a diffusion-equivalent air layer thickness at which the value indicates how long the water vapour takes to migrate through the airtight component. If, for example, the value is 4 m, then this means that the water vapour takes just as long to pass through a convection through an airtight component as it does to pass through a 4 m thick layer of air. Vapour barriers usually have an Sd value of over 1,500 m. All values below this fall within the range of a vapour retarder.

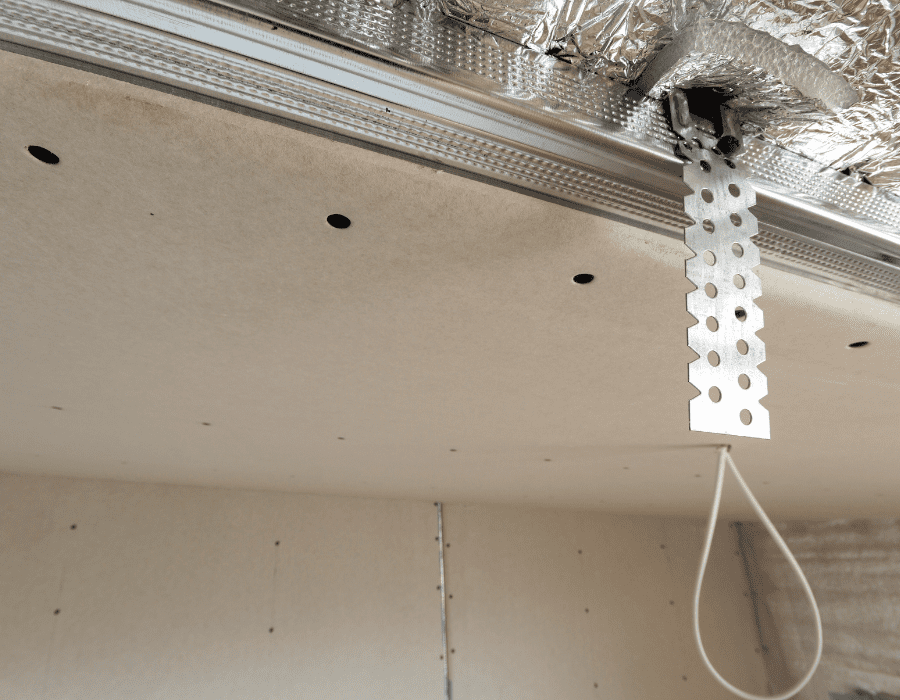

Various foils are well suited for the vapour barrier in order to better protect the thermal insulation against moisture penetration. Glass fiber insulation can be laminated with aluminium foil, for example. This creates an optimum vapour barrier. Aluminium foils are used as vapour barriers since the 1970s.

Aluminium foil can be used as a vapour barrier and also as a vapour retarder, for example when perforated aluminium foil is used.

How useful is the use of aluminium foil as a vapour barrier?

Aluminium foil for roof insulation

Insulating roofs with aluminum foil

Despite the fact that aluminium foil ages faster than other materials, the use of aluminium foil makes sense. A vapour barrier can be produced cheaply with an aluminium foil. With aluminium foil, care should always be taken to ensure that it is glued over a large area.

Public swimming pools, saunas and other wet areas are usually sealed with aluminium foil. But aluminium foil should also be used in the insulation of house roofs. A vapour barrier plays an important role here. It ensures that moist air does not enter

the roof construction can reach. Here it would precipitate as condensation water and cause great damage after some time.

Vapour barrier made of aluminium foil

A vapour barrier made of aluminium foil should always be installed on the room side of the thermal insulation. Otherwise, it can’t work. To ensure that the aluminium foil is processed correctly, many aluminium foils have a label which must point to the inside of the room during processing. A great advantage of high-quality aluminium foils as a vapour barrier is that they are very durable and inexpensive.

Plastic and aluminium foil is the most frequently used of all materials as a vapour barrier. It is usually offered as a roll. A conventional roll of film has a web width of 1.50 m. Many rolls have a length of 50 or 100 m. Aluminium foil is considered to be very resistant, tear- resistant and vapour diffusion-tight. A PE-aluminium laminated vapour barrier is particularly suitable for a vapour-tight construction. If an aluminium foil vapour barrier is installed, then optimum thermal insulation can be achieved. This is 10% higher than without an aluminium foil.

What are the application scenarios for vapour control layers?

If a vapour barrier is not installed professionally, massive moisture damage can occur. This is mainly due to the fact that a construction with a vapour barrier can only be sealed with aluminium foil with difficulty. In most cases, however, it is not the aluminium foil that is to blame, but the workmanship.

If the aluminium foil is not applied correctly, the problem often lies in the area of the connections. In some cases, however, the film can also be damaged when the sockets are attached. If you want to erect a vapour barrier in the attic, sauna, pool area, steam bath or cold store, you have to be very careful with the aluminium foil.

It must also be checked in advance whether the thermal insulation is still damp during installation. In this case, the thermal insulation should not be allowed to dry until it is completely dry. Otherwise, the aluminum foil would prevent the water from the components from evaporating inside. Air-dried components also contain several litres of water per square metre due to the sorption capacity of the material. In this case, an expert should always be consulted before the aluminium foil is used as a vapour barrier. If everything is professionally laid, then aluminium foil offers high quality.

The films are available in various sizes and lengths and can be optimally adapted to any structure. Multilayer metallization films are particularly suitable. They reflect the heat energy and form an additional insulating effect.

Pro / Contra

Simple processing

Pro and Contra of aluminum foil as vapour barrier

The biggest advantage of aluminium foil as a vapour barrier is that it is easy to process. It is very cheap compared to other materials. At the same time, the aluminium foil ensures that the thermal insulation is increased in the case of a vapour barrier.

Heat and radiation reflective

The aluminium foil vapour barrier shields up to 99% of the electromagnetic radiation. Besides, it reflects 50% of the heat. A small disadvantage is that the sheets of aluminium foil must be laid cleanly. Otherwise, they’re not airtight.

Be careful!

You have to work very carefully, because the aluminium foil can tear quickly. Once it has been properly bonded, however, it offers an optimum vapour barrier. A vapour barrier made of aluminium foil can be used on all unventilated and ventilated roofs, i.e. cold and warm roofs. It is ideal for insulating apartments in the attic or facades.

Many films are water vapour proof and also provide good wind insulation. The energy costs of a house can be reduced by using a vapour barrier. A high-quality film prevents heat loss and at the same time protects the thermal insulation from moisture. If required, a rafter-mounted insulation can also be very useful. This is the case, for example, when the roof has already been removed or renovation is pending. The vapour control layer is then simply attached to the underside of the roof insulation.