About the Author:

CEO at AlFiPa, responsible for operations as well as purchasing and sales. He is the primary contact for orders and deliveries within the company.

- Low weight

- Flexible shape

- High energy density

For this purpose, we manufacture foils that make the battery cells safe, sealed, and long-lasting.

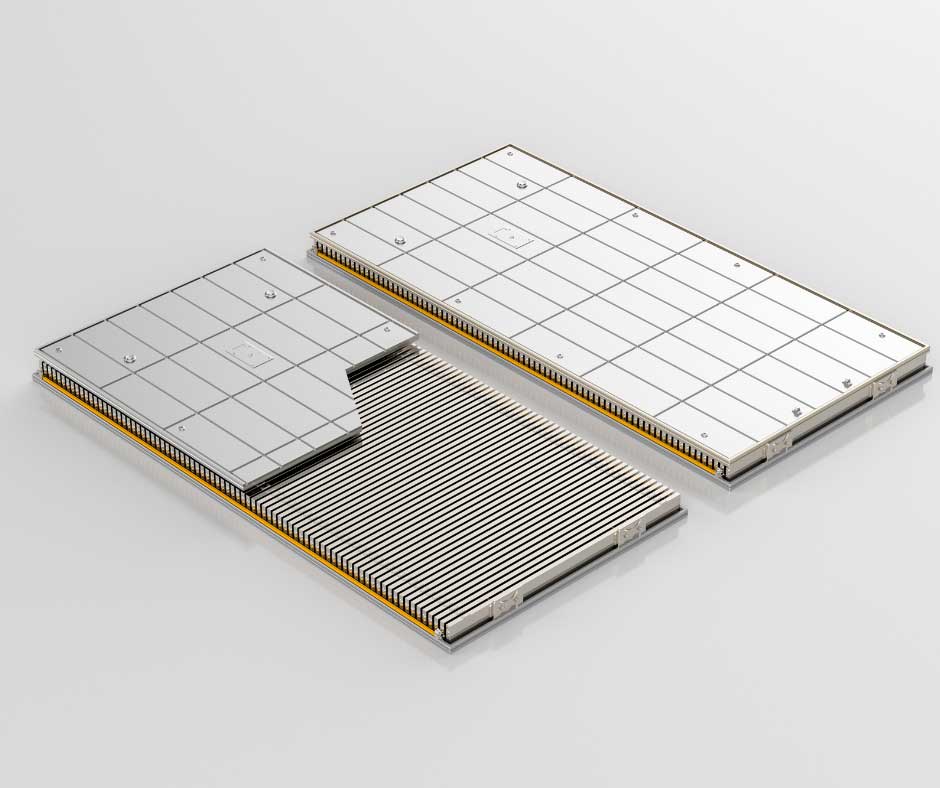

The production of such battery pouches places high demands on the materials. In addition to precise barrier performance and consistent electrolyte resistance, mechanical stability is also important, especially under fluctuating temperature conditions from –20 °C to +60 °C. For thermal management within the battery module, additional foils are used that can be filled with temperature-regulating liquids to stabilize the module’s operating temperature.

Overview of battery cell materials

The pouch lithium-ion battery is a liquid-based lithium-ion battery enclosed by a flexible polymer casing. The main difference compared to other battery types lies in its soft packaging material, an aluminum-plastic composite foil. This foil is also the most critical and technically demanding material in the production of pouch batteries.

The battery pouch foil typically consists of three different layers:

- Outer layer: made of Nylon (PA), BOPA, or PET, providing mechanical protection

- Middle layer: made of aluminum foil, serving as an effective barrier against gas, water, and UV radiation

- Inner layer: made of CPP or nylon, ensuring reliable sealing and electrolyte resistance

The combination of these layers enables a sealed, durable, yet flexible cell casing. Additionally, a thin foil containing temperature control fluid is often placed between individual cells to prevent overheating and optimize performance. Due to their sensitive structure, pouch batteries also rely on highly precise battery management systems (BMS) that monitor charge level, temperature, and cell voltage. Modern foils also use advanced lamination techniques to achieve even better barrier properties and compatibility with various cell chemistries.

Battery Foils

In which applications are battery pouches used?

The range of applications for pouch cells is diverse and reflects their flexibility, as they are used across various industries.

Consumer electronics

Examples: smartphones, tablets, laptops, power banks, headsets, smartwatches

Advantages: compact design with low weight, adaptable shape for custom designs, high energy density in limited space

E-mobility and automotive

Examples: electric vehicles, hybrid vehicles, e-bikes, e-scooters

Advantages: good cooling due to flat design, adaptability to specific vehicle layouts, modular structure for scalable battery systems

Aerospace technology

Examples: drones, aircraft systems with electrical components, satellites, space modules

Advantages: low weight with high energy capacity, energy efficiency in confined space and weight conditions

Medical technology and industry

Examples: portable medical devices (e.g. infusion pumps, ECG systems), implantable devices (e.g. neurostimulators), power tools (drills, saws), industrial systems (such as backup power or robotics)

Advantages: compact and reliable power supply, long service life, robustness and safety for medical use

Stationary energy storage systems (ESS)

Examples: home storage linked to photovoltaic systems, off-grid systems, large-scale storage units (e.g. containerized solutions for grid stabilization), research and pilot projects in energy technology

Advantages: scalable and durable, stable cell chemistry for long-term operation, supports renewable energy through intermediate storage, suitable for peak load management and emergency power supply

Since 2005, NASA has also used battery pouches in its space missions due to their safe, lightweight, and efficient characteristics.

What battery developers should consider when selecting foils

Choosing the right composite foil is the first step in developing safe and efficient lithium-ion cells. In battery pouches, the casing is not only protective but also an integral part of the cell and must withstand significant chemical, mechanical, and thermal stress.

- Layer structure & thickness: the thickness of each layer affects not only the weight but also barrier performance and tear resistance.

- Roll widths: available widths vary depending on cell size and further processing (e.g. punching, deep drawing).

- Chemical resistance: the inner sealing layer must be resistant and impermeable, especially to electrolytes such as lithium salts or organic solvents.

In addition to material properties, processing characteristics should also be evaluated, such as formability, sealing temperature, and long-term stability under mechanical stress.

Separators and composite foils in lithium-ion cells

The performance and safety of lithium-ion batteries depend on their materials, especially the invisible components inside and on the surface. While separator foils control ion flow within the battery core, barrier layers protect the cell from external influences. Both must withstand extreme conditions, but their functions and properties differ fundamentally.

Separator foils (usually made of PE or PP) separate the anode and cathode, allowing ions to pass through while blocking electrons, a key function for safe operation. Aluminum-plastic composite foils, on the other hand, encase the cell and protect it from moisture, gases, and mechanical stress.

Innovative material designs now combine both functions, enabling more compact or particularly fail-safe batteries.

Battery pouches offer several advantages and disadvantages, but the growing demand for them is undeniable. Their efficient, flexible, and compact design opens up new possibilities compared to other battery types. Therefore, it is crucial to focus on high-quality foils during production.

What matters when selecting foils for batteries

The right foil determines the safety, performance, and longevity of pouch cells. Before choosing a material, the following aspects should be evaluated:

- Impermeability: the foil must reliably protect against moisture, oxygen, and UV radiation.

- Resistance to electrolytes: especially important when exposed to aggressive substances such as lithium salts or organic solvents.

- Robustness: it should withstand mechanical stresses such as pressure, bending, or vibration.

- Processability: must integrate smoothly into existing production processes, whether for deep drawing, sealing, or specialized cell formats.

- Heat resistance: low thermal shrinkage and high temperature stability are essential.

We are happy to assist you in finding the optimal composite foil tailored to your specific cell type and application area.

What sizes are available?

From standard widths to custom-made solutions, we supply precisely according to your requirements. Simply contact us.

| Thickness | 153 µm (±0,005 mm) |

| Maximum width | 480 mm (±0,5 mm) |

| Length per roll | 250 m (±5 mm) |

| Roll core | 76 mm (3″) |

FAQ

-

What is the difference between pouch and prismatic cells?

Pouch cells are flat and flexible, while prismatic cells are rigid and rectangular. Pouch cells can be more easily adapted to various housing shapes but require more robust casings. -

Which materials are suitable for battery pouch foils?

Typically, three-layer composite foils made of nylon, aluminum, and CPP are used. This combination provides mechanical strength, barrier performance, and electrolyte resistance. -

How are battery pouch foils manufactured?

Usually through extrusion lamination or dry-bond lamination with high precision. -

What temperature ranges can battery pouch foils withstand?

Standard range: –20 to +60 °C; higher temperatures possible with special configurations. -

How long do the foils last in battery systems?

When properly processed and used, the foils can achieve a service life of several years or charge cycles, depending on the cell type and application.

We are among Europe’s leading suppliers of foils for insulation, packaging, and industrial applications, with over 40 years of expertise at AlFiPa. Our team offers comprehensive advice on all technical topics and applications. Feel free to contact us with your questions at any time!