About the Author:

CEO at AlFiPa, responsible for operations as well as purchasing and sales. He is the primary contact for orders and deliveries within the company.

Application areas include industries such as construction, electrical engineering, food processing, and medical technology. In these fields, it is often used for sealing, insulation, cladding, or decorative purposes.

Specialized Film Solutions

Stainless steel foils

Stainless steel encompasses hundreds of alloys. These offer various properties that are advantageous for specific applications. Stainless steel foils are typically made from austenitic, ferritic, martensitic, or duplex alloys, including grades such as 1.4301 (AISI 304), 1.4401 (AISI 316), 1.4404 (AISI 316L), 1.4541 (AISI 321), and 1.4828 (AISI 309).

Austenitic Stainless Steel Foils

Austenitic stainless steel foils are non-magnetic and corrosion-resistant, making them ideal for the food and chemical industries.

Ferritic Stainless Steel Foils

Ferritic stainless steel foils are magnetic, highly resistant to acids, and very cost-effective.

Martensitic Stainless Steel Foils

Martensitic stainless steel foils are hardenable, wear-resistant, and ideal for mechanical components.

Duplex Stainless Steel Foils

Duplex stainless steel foils combine austenite and ferrite, making them ideal for applications requiring high strength and resistance to chlorides.

Comparison of Stainless Steel Types

The different types of stainless steel vary in composition and therefore in their characteristics. The following table provides an overview of their various properties:

| Property | Austenitic Stainless Steel | Ferritic Stainless Steel | Martensitic Stainless Steel | Duplex Stainless Steel |

|---|---|---|---|---|

| Corrosion resistance | Very high | High | Medium | Very high |

| Magnetic | No | Yes | Yes | Yes |

| Cost-efficiency | Medium | Very high | High | Medium |

| Heat resistance | High | Medium | Medium | Medium – High |

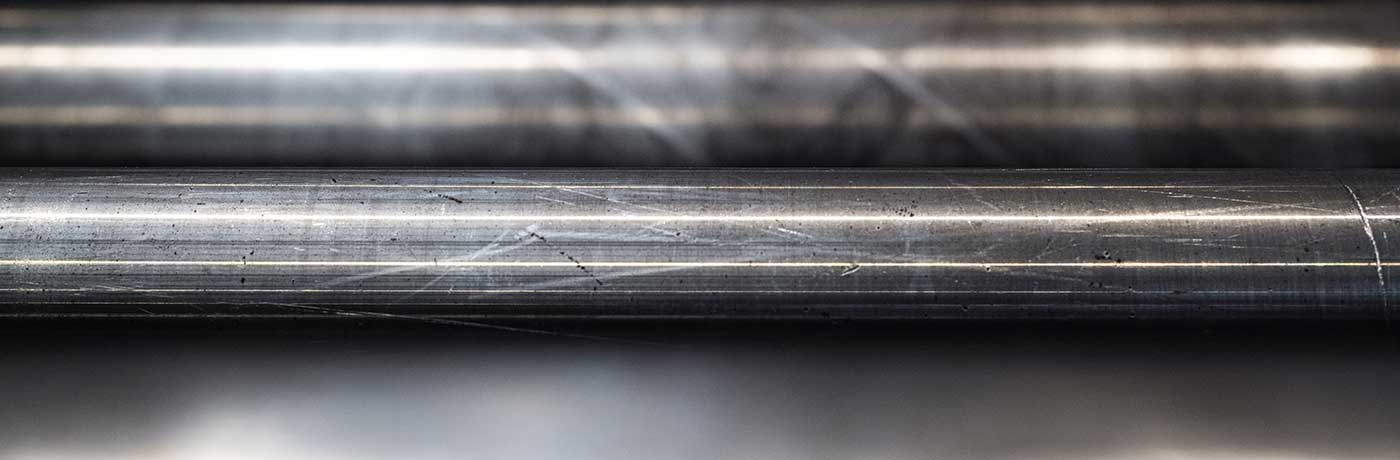

Surfaces and Finishes of Stainless Steel Foils

Stainless steel foils are available in various surface qualities that meet both aesthetic and functional requirements.

Rolled (Industrial) Finishes

- 1D – Hot-rolled, pickled, rough and matte gray, non-decorative surface

- 2D – Cold-rolled, pickled, uniformly matte, smoother than 1D

- 2B – Cold-rolled and lightly polished; bright, smooth, slightly glossy

- BA (Bright Annealed) – Bright annealed, mirror-like, decorative

- TR (Temper Rolled) – Mechanically smoothed, high flatness and strength

Mechanical Finishes

- Ground – Surface treated with abrasive belts; matte to fine depending on grit

- Brushed – Mechanically brushed; fine, uniform line texture

- Polished – High gloss, mirror-like or slightly shiny; decorative and hygienic

Special or Functional Finishes

- Glass bead blasted – Uniformly matte surface with low reflectivity

- Etched (textured) – Patterns or textures created through chemical etching or rolling

Advantages of Stainless Steel Foil

- Corrosion resistance – Withstands acids, alkalis, and oxidation

- High strength – Stable and durable despite thin gauge

- Heat resistance – Maintains shape under high temperatures

- Low magnetism – Ideal for electronics and precision components

- Smooth surface – Clean and resistant to contamination

- Easy to process – Weldable, cuttable, and formable

Stainless steel foils remain dimensionally stable even under extreme conditions. This makes them suitable for applications where other materials fall short. In addition, the smooth, hygienic surface is easy to clean and resistant to chemical exposure, making it ideal in terms of microbial resistance. Furthermore, flexible and thin stainless steel foils allow for precise adaptation to complex shapes, while coated or multi-layer stainless steel composite foils provide additional protection and enhanced insulation properties.

Comparison of Aluminum Foils and Stainless Steel Foils

In contrast to aluminum foil, stainless steel foil stands out for its higher strength, heat resistance, and chemical resistance. This makes it an essential material for industrial and technical applications.

| Property | Aluminum Foil | Stainless Steel Foil |

|---|---|---|

| Weight | Very lightweight, easy to process | Significantly heavier, but dimensionally stable |

| Thermal conductivity | High – ideal for heat and cold reflection | Lower – but heat-resistant |

| Strength & durability | Soft, easily deformable | High strength and wear resistance |

| Temperature resistance | Suitable for moderate temperatures | Stable even at extreme temperatures |

| Maintenance & lifespan | Low-cost but less durable | Durable, low-maintenance, highly resistant |

| Typical applications | Packaging, insulation, reflectors | Insulation, technical components, decorative finishes |

Aluminum foil is suitable for lightweight, flexible applications, while stainless steel foil impresses with its stability, durability, and robustness, making it ideal for demanding industrial use.

Application Areas

Stainless steel foils

The choice between austenitic, ferritic, and martensitic stainless steel foils depends on the specific properties of each type.

Austenitic Stainless Steel

Austenitic foils are used wherever maximum corrosion resistance and formability are required.

Anwendungsbereiche:

- Food technology (equipment, surfaces)

- Medical technology (instruments, packaging)

- Chemical industry

- Electronics (shielding, precision components)

- Construction, decorative elements

Ferritic Stainless Steel

Ferritic foils are preferred for applications where cost-effectiveness, moderate corrosion resistance, and magnetism are important.

Anwendungsbereiche:

- Automotive industry (exhaust systems, heat shields)

- Household appliances (ovens, sinks)

- Construction industry (facades, roofs)

- Energy/thermal engineering (heat exchangers)

Martensitic Stainless Steel

Martensitic foils are used when components must be extremely hard and load-bearing, such as for cutting tools or technical springs. They can be further hardened through heat treatment and are therefore the right choice for mechanically stressed components.

Anwendungsbereiche:

- Cutting tools (knives, scissors)

- Surgical instruments

- Springs, fastening elements

- Components subjected to high mechanical loads (valves, pump shafts)

Duplex Stainless Steel

Duplex stainless steel foils are ideally suited for high-performance environments with demanding corrosion and strength requirements.

Anwendungsbereiche:

- Offshore and seawater technology

- Chemical plants and reactors

- Energy and environmental technology

Processing, Sizes & Delivery

We offer stainless steel foils both as roll material and as custom-cut pieces.

| Material | Typical alloys | Thickness | Width | Length (sheet) | Standards |

|---|---|---|---|---|---|

| Stainless steel foil | 1.4301 / 1.4401 / 1.4541 / 1.4828 | 15 µm (0.015 mm) to 3 mm | 3 mm to 1,000 mm | 80 mm to 3,000 mm | EN 10088-2 / ASTM A240 |

In addition to standard formats, custom dimensions in individual widths, lengths, and thicknesses are also available. Upon request, we also handle finishing and packaging so that the foils are ready for your further processing.

FAQ

Which stainless steel alloys are available?

We offer austenitic, ferritic, martensitic, and duplex stainless steel foils in various alloys.Can I order stainless steel foils in custom sizes?

Yes, we supply standard and special formats, roll material, or custom-cut pieces according to customer requirements.

Our team will be happy to provide detailed advice on all topics and technical applications. Feel free to contact us with any questions!