About the Author:

CEO at AlFiPa, responsible for operations as well as purchasing and sales. He is the primary contact for orders and deliveries within the company.

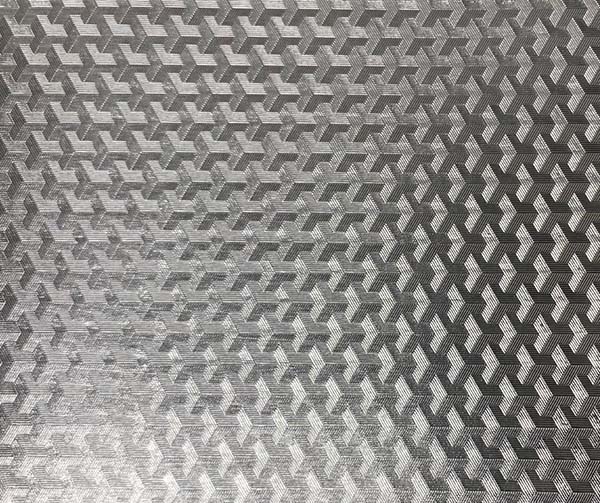

In this material, smooth aluminum foil is processed through rolling or embossing techniques. This creates concave and convex structures that enhance the foil’s mechanical properties and add a decorative surface.

Advantages of embossed aluminum foil

Embossed aluminum foil offers numerous benefits:

- Stability and strength: Embossing improves mechanical performance, making the foil more resistant to tearing, wrinkling, and mechanical stress.

- Crumple and blocking resistance: The structured surface prevents the foil from sticking together easily and helps it retain its visual appeal over time.

- Functional versatility: The embossed texture increases reflection, thermal insulation, and in some cases even heat dissipation.

- Decorative appeal: Various patterns give the foil a premium appearance—particularly relevant for cosmetic, chocolate, or gift packaging.

- Processing compatibility: Despite embossing, the foil remains flexible and can be laminated, coated, lacquered, or printed.

Embossed aluminum foil vs. smooth aluminum foil

Embossed aluminum foil combines the positive properties of aluminum with additional functional and visual advantages. But how exactly does embossed foil differ from smooth aluminum foil in direct comparison?

Comparison

| Comparison | Embossed aluminum foil | Smooth aluminum foil |

|---|---|---|

| Mechanical strength | Higher stability, more resistant to tearing and wrinkling | More susceptible to pressure damage |

| Tensile strength | Structure enhances tensile strength | Easier to damage |

| Crease resistance | Fewer creases, more uniform appearance | Prone to creasing |

| Flexibility | Adapts better to uneven surfaces | Less adaptable to uneven surfaces |

| Thermal insulation | Air pockets within the structure improve insulation | Weaker insulation properties |

| Sound insulation | Embossing reduces sound transmission | Minimal sound insulation |

| Moisture and corrosion protection | More resistant in humid environments | More prone to oxidation |

| Appearance and feel | Decorative texture with a high-quality look | Neutral, less decorative |

| Wear resistance | Scratches less noticeable | Wear clearly visible |

| Reflection | Diffuses light, non-glare | Mirror-like reflection |

| Typical applications | Premium packaging, building insulation, automotive, technical uses | Standard packaging, basic applications |

| Signs of use | Minor pressure marks and fingerprints are less visible | Dents and pressure marks are easily visible |

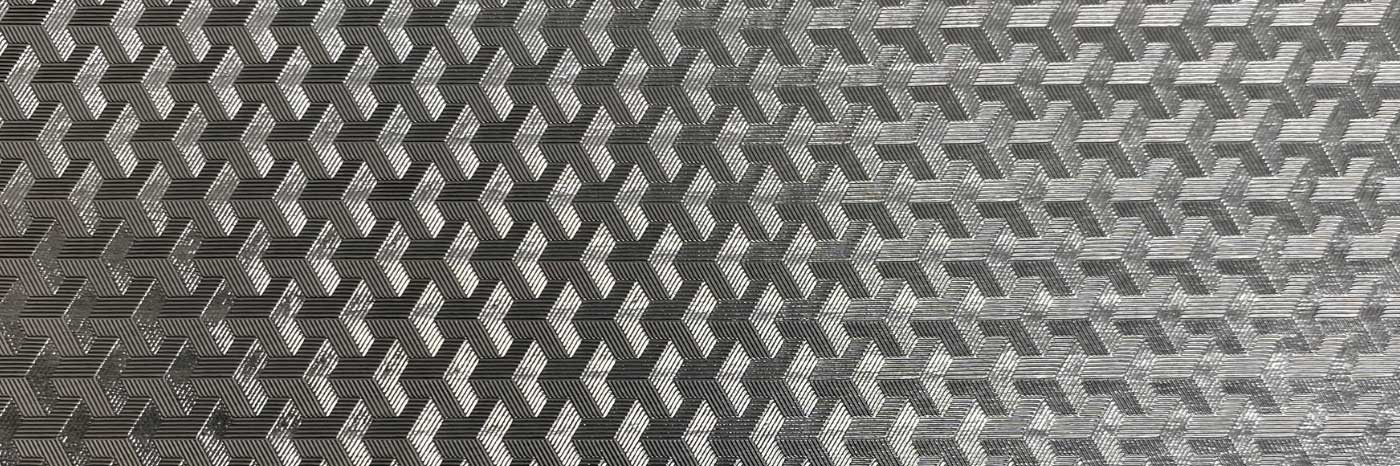

Embossing Patterns

Embossed aluminum foil is available in countless pattern and logo print variations. Each design offers specific advantages in terms of appearance or functionality:

- Gross Grain / Fine Gross Grain: commonly used for logos and brand embossing

- Damask: fine, decorative pattern for premium packaging

- Calotte (hemispherical embossing): increases contact surface and improves heat dissipation, e.g. in automotive applications

- Rhombus and diamond patterns: aesthetic and functional, frequently used in architecture and packaging

- Orange Peel: classic texture, common in refrigeration equipment, pipe insulation, and façades

- Ribbed: provides additional stiffness

- Other patterns: hammered, water wave, or worm structure, each with unique decorative or technical properties

Applications

Embossed aluminum foil is used across many industries. Some typical applications include:

Packaging

- Food packaging: Thanks to its barrier properties and sealability, the foil protects against oxygen, light, and moisture. Examples include embossed chocolate wrappers and yogurt lids that combine product protection with visual appeal.

- Pharmaceutical packaging: Blister packs benefit from high stability and hygienic characteristics. Medications remain protected from external influences.

- Cosmetic packaging: Premium products gain an additional quality feature through embossed closures and labels.

- Gift packaging: Metallic textures and decorative patterns enhance the attractiveness of luxury products.

- Tobacco and confectionery packaging: Cigarette packs use embossed aluminum foil for the same reasons as chocolate, offering both protection and a decorative finish.

Construction & Building

- Vapor barriers and insulation: Embossed aluminum foil composites protect against moisture and provide efficient thermal insulation.

- Bitumen roofing membranes: The embossed aluminum foil serves as the top layer, reflecting heat and protecting the roof surface.

- Pipe insulation: Colored variants, such as red and blue embossed insulation sleeves, are used in heating and underfloor heating systems.

- Architecture & decoration: Wall and ceiling panels benefit from the visual and functional advantages of textures like orange peel.

Automotive

- Thermal protection: Embossed aluminum foil is used for heat shields in engine compartments, exhaust systems, and engine covers.

- Sound insulation: The structured surface reduces noise transmission within vehicle cabins.

- Decorative applications: Metallic textures in interiors create high-end visual accents.

Technology & Industry

- Refrigeration equipment and heat exchangers: Orange peel embossing improves convection and heat dissipation.

- Electrical insulation: In combination with kraft paper or other materials, embossed foil is used in transformers and cables.

- Composites: As a top layer in sandwich structures, the foil provides stability and protection.

Surface Treatments

Embossed aluminum foil can be further refined with additional surface treatments:

- Lacquered: Protective or colored coatings enhance corrosion resistance and decorative appeal.

- Laminated material: Polyester or PU layers improve mechanical strength.

- Anodized: The foil receives a dense oxide layer that increases corrosion and wear resistance.

- Printed: Patterns, text, or images expand design possibilities.

- Self-adhesive: Simplifies application since no additional adhesives are required.

FAQ

Can I order embossed aluminum foil in custom sizes?

Yes, both cut-to-size sheets and roll stock are available in standard and custom dimensions.Which patterns are available?

Common ones include Gross Grain, Fine Gross Grain, Damask, Calotte, Rhombus, Ribbed, Orange Peel, as well as Water Wave or Hammered.What surface treatments are possible?

Anodizing, lacquering, laminating, printing, and self-adhesive variants.Is the foil suitable for food use?

Yes, it is hygienic, sterilized, and free from harmful substances.What are the main advantages over smooth foil?

Greater stability, improved insulation, decorative appearance, and longer durability.

AlFiPa is one of Europe’s leading companies in the field of industrial foils. With over 40 years of experience, you are in the best hands with us.

Do you have any questions or need expert advice? Our team will be happy to assist you, contact us today!