About the Author:

CEO at AlFiPa, responsible for operations as well as purchasing and sales. He is the primary contact for orders and deliveries within the company.

But what exactly makes copper foil so valuable compared to other foils, such as aluminum foil?

Copper Foil & Aluminum Foil – Advantages and Disadvantages

| Copper Foil | Aluminum Foil |

| Advantages Excellent electrical conductivity Greater shielding effectiveness (EMI/RFI) than aluminum, for example, at the same thickness (especially at higher frequencies) Easy grounding and solderability Flexible and formable Available as ED and RA copper foil Compatible with laminates, carrier, and adhesive layers | Advantages Lighter foil Good thermal insulation Not very prone to oxidation Significantly more affordable than copper foil |

| Disadvantages Prone to oxidation if not additionally protected Significantly more expensive than aluminum foil | Disadvantages More susceptible to reactions with acids Lower shielding effectiveness More difficult to solder |

| Applications EMC shielding Printed circuit boards Grounding | Applications Insulation Technical applications Packaging for food or pharmaceuticals |

When is copper foil the best option for you?

- Electrical conductivity

- Low signal loss

- Flexibility and formability

- EMI shielding

copper foil provides greater shielding effectiveness than aluminum foil at the same thickness.

What are the typical applications of copper foil?

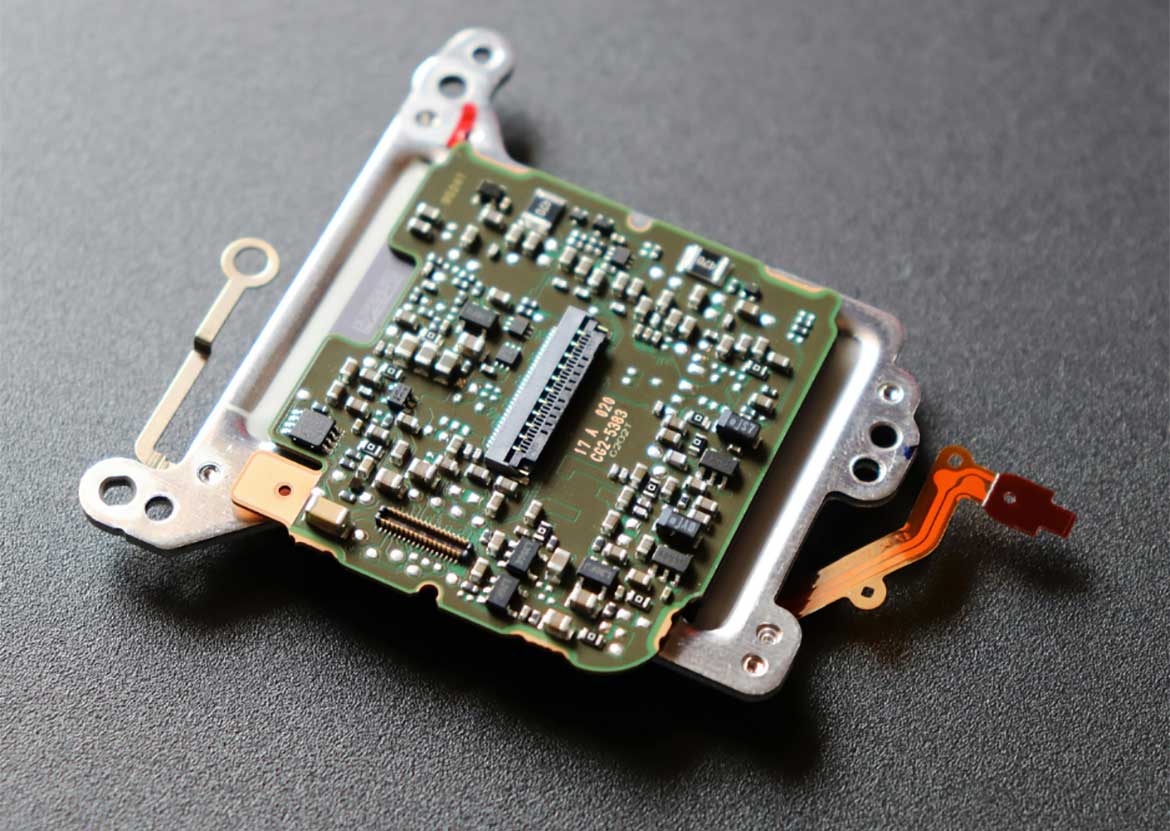

- Printed circuit boards: Copper foil forms the base material for printed circuit boards. Rolled copper foils are used for flexible PCBs due to their high ductility, while electro-deposited copper foils are more commonly used for rigid boards.

- Lithium-ion batteries: Copper foil serves as a current collector in lithium-ion batteries. It improves battery performance by allowing efficient energy transfer during charging and discharging thanks to its high conductivity.

- EMC shielding foils: Owing to its excellent electrical conductivity, copper foil is ideally suited for electromagnetic shielding in various electronic devices. It can block both electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring the proper functioning of sensitive equipment.

These applications highlight the versatility of copper foil and make it indispensable across many industries. But how exactly is it used?

Electronics: Whether smartphones, laptops, or televisions – almost every electronic device contains printed circuit boards (PCBs). Here, copper foil acts as the conductive layer that reliably transmits current and signals.

Automotive industry: In electric and hybrid vehicles, lithium-ion batteries use copper foil as the current collector on the anode side. Additionally, numerous printed circuit boards are used in vehicle electronic systems.

Photovoltaics: In solar cells, copper foil efficiently conducts the generated current, helping to maximize the use of solar energy.

Battery manufacturing: Copper foil is the standard anode material in lithium-ion batteries – without it, high-performance batteries for phones, electric vehicles, and other devices would not be possible.

Energy sector: In transformers and generators, copper foil is wound around magnetic cores to conduct current. It is also used in switchgear for contacts and switching mechanisms.

Medical field: Thanks to its biocompatible and antimicrobial properties, copper foil is used as an electrode in medical devices such as ECGs. It is also applied in implants and wound dressings.

What are RA and ED foils, and how are they manufactured?

The flexibility of copper depends on several factors. In addition to its thickness (or thinness), the grain structure of the copper also affects flexibility. There are two common types of copper used in the market for printed circuit boards and flexible circuits: ED (Electro-Deposited) and RA (Roll Annealed).

Roll Annealed (RA)

Roll Annealed (RA) copper foil is a type of copper foil that undergoes an annealing process to improve its flexibility, surface smoothness, and electrical conductivity. This type is widely used in the electronics and battery industries, particularly in the production of flexible printed circuit boards and lithium-ion batteries.

Its grain structure and smooth surface make it ideal for dynamic, flexible circuit applications. Another key application area is in high-frequency signal and transmission technologies. It has been proven that the surface roughness of copper can influence insertion loss at high frequencies, making a smoother copper surface advantageous.

Electro-Deposited (ED)

Electro-deposited (ED) copper foil comes in a wide range of variants with different surface roughness levels, treatments, and grain structures. In general, ED copper foils feature a vertical grain structure.

Compared to roll-annealed (RA) copper, standard ED copper typically has a relatively high profile or rougher surface. ED copper tends to be more rigid and does not promote good signal integrity. It is unsuitable for fine circuit lines and has poor bending strength, which is why RA copper is used for flexible printed circuits.

However, ED copper can also be used effectively in dynamic applications depending on its design. In fact, for thin, lightweight consumer applications that require high cycle rates, it is often the preferred choice.

PCB board. Copper foils

Which copper foil is the right one: RA copper foil vs. ED copper foil

The choice between RA and ED copper foils depends on the specific applications and individual requirements. RA copper foil is particularly suitable for flexible printed circuit boards (FPC) due to its high conductivity and strong flexibility. Through the rolling process followed by annealing, the foil gains its high ductility and elongation capacity.

ED copper foil, on the other hand, offers improved adhesion thanks to its rough surface, making it ideal for applications where flexibility is less critical. It is especially well-suited for rigid printed circuit boards (PCBs).

The direct comparison below highlights the respective strengths of both foil types at a glance.

RA and ED copper foils compared:

| RA | ED |

| Flexibility Relatively high | Flexibility Relatively low |

| Manufacturing Complex (rolling and annealing) | Manufacturing Simple (electro-deposited) |

| Cost Relatively high | Cost Relatively low |

| Application Flexible printed circuit boards, high-frequency applications, mobile devices | Application Rigid printed circuit boards (standard PCBs), cost-sensitive applications, electromagnetic interference (EMI) shielding |

| Structure Horizontal orientation | Structure Vertical orientation |

| Surface Smooth on both sides, can be roughened | Surface One side rough, good adhesion |

Which sizes are available?

Our copper foils are available in various thicknesses and formats and can be supplied either as rolls or as custom-cut sheets.

| Thickness | Width | Length (sheet) |

| 50 µm, 100 µm up to 3 mm | 600 mm / 1.000 mm | 80 mm to 3,000 mm |

Special dimensions and custom cuts are also available upon request.

FAQ

Can I request custom sizes and individual dimensions?

Yes, you can order both standard and custom-sized cuts from us!How do RA and ED copper foils differ?

RA copper foil is produced through rolling and annealing, resulting in an extremely flexible and ductile foil ideal for dynamic applications such as flexible printed circuit boards.

ED copper foil is electrochemically deposited on a rotating drum, making it less flexible and the standard choice for most rigid printed circuit boards, though it offers lower bending strength.

We offer both standard and custom dimensions, whether for roll widths, core diameters, customer-specific cuts, or other requirements.

Do you have further questions or need expert advice? Our team will be happy to assist you, contact us today!