About the Author:

CEO at AlFiPa, responsible for operations as well as purchasing and sales. He is the primary contact for orders and deliveries within the company.

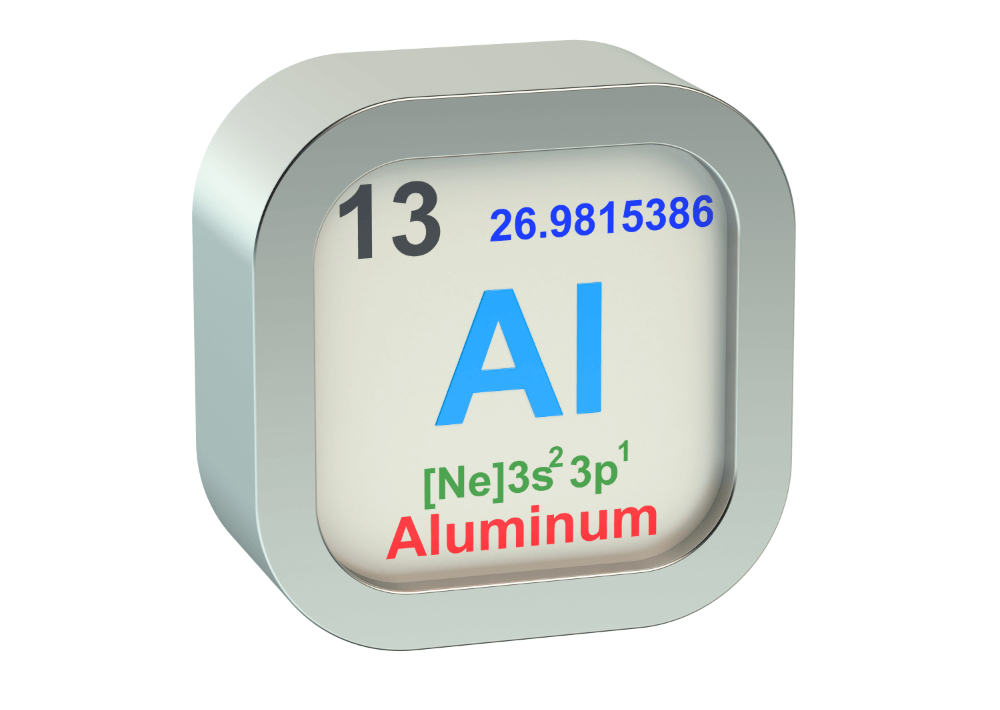

Aluminium is a natural material that is often used because of its good conductivity. It is malleable and equipped with a very noble surface. The chemical element aluminium has the atomic number 13. The name is derived from the Latin word alumen or alum.

In chemistry, aluminium belongs to the boron group in the periodic table of the elements. It used to belong to the group of earth metals. Aluminium is the third most common element and most common metal present in the earth’s crust. Because of its reactivity, it often occurs only in a chemically bound state. Today, aluminium foil is mostly made from pure aluminium (Al content 99 to 99.9%). For the production, pre-rolled strips with a thickness of 0.6 to 1.5 mm are produced with several rolling steps to the required thickness.

Milling of aluminium foil

If very thin foils are required for the chemical industry, other industry or for the household

Thin aluminium foils are milled in two layers. This creates the two different surfaces. While one surface is glossy (sometimes also called glossy), the other side is rather matt due to repeated forming. The rolling process makes the aluminium somewhat hard and brittle. So that it is flexible and soft again, it is subsequently soft annealed. Aluminium foil can be produced in chemistry with potassium amalgam and aluminium chloride. In this case potassium serves as a reducing agent. The formula in the chemistry for such a film is: 4AICI3+3K – AI + 3 KAICI4.

Properties of aluminium foil in the chemical and food industries

Aluminum foil in chemical and food sectors

Aluminium foil in the chemical and household industries is usually 0.010 to 0.015 mm thin. For gastronomy, aluminium foils are often used on 30 cm or 50 cm rolls. Many foodstuffs can be packed in the aluminium foil in a light-tight way. This keeps them fresh longer. This is mainly due to the fact that the food is covered airtight. For this reason, aluminium is not only used in the chemical industry, but also in households.

Aluminium foil has the advantage that it emits very little aroma. Only a small part of the moisture in some foods can escape. Therefore, the food does not dry out quickly. Only special foods, lye pastries, vinegary marinades, sauerkraut, sliced citrus fruits, tomatoes and fruit acids should be handled carefully with aluminium foil. In this case, corrosion occurs and the aluminium discolours dark to black.

Sometimes aluminium can even dissolve completely when it comes into contact with certain acids.

In chemistry, aluminium is not very temperature-sensitive. Many grill fans put their meat or vegetables on an aluminium foil so that the moisture does not get lost and the barbecue food stays juicy. In chemistry, the melting point of aluminium is 660.32 °C. The boiling point of aluminium, on the other hand, is 2,500° C. Aluminium is therefore often used for cooking pots, beverage cans and food cans.

Aluminium pots are often used for camping purposes in particular.

How does aluminium foil react in chemistry?

Chemists often test what aluminium reacts to. After all, it is used in a variety of ways, for example in food packaging, hairdressing and industry.

Within a very short time, aluminium forms a micrometer-thick layer of aluminium oxide on the surface. It protects against a reaction with water. If this thin film is destroyed, a chemical reaction of the aluminium can be detected. In combination with water, a highly flammable hydrogen gas is formed. Aluminium chloride is considered hydrolysing in water. A fine mist forms in the air. The reaction with water vapour can even lead to small drops of hydrochloric acid forming on the aluminium foil.

The aluminium ions on the aluminium foil in combination with other compounds also undergo hydrolysis. This can progress until the cation no longer has any charge. This compound may result in the formation of insoluble hydroxide. The beginning of hydrolysis in chemistry is: Al3+(aq) + 6H2O(l) <-> [Al(H2O)6]3+(aq).

In chemistry, aluminium foil reacts very violently with sodium hydroxide. This reaction is used by many pipe cleaning agents. But also the reaction in chemistry with bromine can be very violent. This chemical compound can cause flame phenomena at room temperature. The resulting aluminium bromide can form aluminium hydroxide and hydrobromic acid in combination with water in the chemical industry. In combination with mercury, on the other hand, aluminium foil forms an amalgam.

The light aluminium foil often has a silver-grey, dull appearance due to a very thin oxide layer forming in the air. Pure aluminium foil has an impenetrable oxide layer. Therefore, this aluminium foil is corrosion resistant. In chemistry, the protective oxide layer can be strengthened by electrical oxidation. Although aluminium foil is very soft, it is also tough. The tensile strength of pure aluminium in chemistry is around 49 MPa. The tensile strength of the alloy is between 300 and 700 MPa.